1. Make sure your HVAC system is working properly.

a. Provide and maintain at least required minimum outdoor airflow rates for ventilation a specified by applicable

codes and standards

b. Outdoor air should not have viral particles in it unless the air is pulled from a place where people congregate.

We assume it is clean for controlling COVID-19 transmission. This does not mean it is clean for any other

purpose. Maintain usual filtration. HVAC filters installed to filter ONLY outdoor air do not need to be upgraded

to protect from COVID-19 transmission.

c. Any filters should be sealed to ensure air goes through the filters, instead of around or between them

2. Reduce viral particles in breathing air by one or more of the following based on what the building and HVAC can

reasonably do.

a. Source control – fewer people, masks, social distancing

b. Increased outdoor air through HVAC or windows

c. Better filtration or other supplemental air cleaning in HVAC or occupied spaces

3. Combine filters and air cleaners to achieve MERV 13-equivalent or better levels of performance for air cleaning

a. Increase the efficiency of HVAC filters to remove more virus containing particles.

i. MERV 13 filters are not required, but the ETF suggests them as one good option. MERV 13 filters remove

≥85% of 1-3 um particles. Higher efficiency filters would remove more in each pass through the filter.

ii. The filter must be sealed well to work as expected. A lower efficiency filter may give better performance if

the seal is better and/or the airflow is higher.

iii.Charged media filters are likely to drop in efficiency with use. It is best to use MERV-A rated filters when

the rating is available, as the MERV-A rating takes any drop in expected performance into account.

iv. When upgrading filters, only do so if your system can handle it

1.look for pressure drop issues for the fan

2.make sure any new filters can be sealed in well

3.make sure the filter you chose works in your environment

v.Run the HVAC whenever there are people present. The filter does not work unless the air flows

through it.

vi.If you have pre-filters and filters, you do not need to upgrade both filters. That would be likely to

cause unacceptable pressure drop increases.

b. In-room air cleaners

i. When HVAC air cleaning is not sufficient, consider using in-room air cleaners. Only use air cleaners

for which evidence of effectiveness and safety is clear.

ii. Consider using in-room units in conjunction with HVAC filters to meet a clean air exchange level or a

specific number of air changes per hour (ACH).

iii.Use the AHAM Clean Air Delivery Rate (CADR) to properly size air-cleaners for a given space.

iv.High-efficiency particulate air (HEPA) or other filters with high particle removal efficiency in the unit

are recommended.

c. Other air cleaning technologies – Seek testing data that shows efficiency and occupant safety under

conditions consistent with the intended use before selecting these air cleaners.

4. Dilution of COVID

a. The clean or cleaned air should be directed into the breathing zone in each occupied space

b. Air vents or exhaust from in-room air cleaners should not create strong air currents

c. Return air vents to HVAC or in-room units should pull air from the room and not directly from the clean

air inlet

5. Select control options, including in-room filters and air cleaners, that provide desired exposure reduction

while minimizing associated energy penalties.

CDC Science Brief on Transmission

Updated May 7, 2021

- The principal mode by which people are infected with SARS-CoV-2 (the virus that causes COVID-19) is through exposure to respiratory fluids carrying infectious virus. Exposure occurs in three principal ways:

1. Inhalation of very fine respiratory droplets and aerosol particles.

2. Deposition of respiratory droplets and particles on exposed mucous membranes in the mouth, nose, or eye by direct splashes and sprays.

3. Touching mucous membranes with hands that have been soiled either directly by virus-containing respiratory fluids or indirectly by touching surfaces with virus on them.

- The risk of SARS-CoV-2 infection varies according to the amount of virus to which a person is exposed.

- Transmission of SARS-CoV-2 from inhalation of virus in the air farther than six feet from an infectious source can occur.

- The complete CDC Science Brief can be found HERE.

Modes of Transmission

- See ASHRAE Statements on Airborne Transmission and the Environmental Health Emerging Issue Brief, “Pandemic COVID-19 and Airborne Transmission.”

- Recognize That Virus May Be Aerosolized During Toilet Flushing, even in subsequent flushes following initial use by an infectious person.

- Keep plumbing traps full of water or mineral oil to avoid transmission of sewer aerosols through dry traps. SARS-CoV-1 and SARS-CoV-2 have both been shown to be transmitted this way, and two SARS-CoV-2 published studies posited transmission in a similar manner.

Airborne Transmission Statement & Core Recommendations

ASHRAE Statement on airborne transmission of SARS-CoV-2:

- Airborne transmission of SARS-CoV-2 is significant and should be controlled. Changes to building operations, including the operation of HVAC systems can reduce airborne exposures.

ASHRAE Statement on operation of heating, ventilating, and air-conditioning systems to reduce SARS-CoV-2 transmission:

- Ventilation and filtration provided by heating, ventilating, and air-conditioning systems can reduce the airborne concentration of SARS-CoV-2 and thus the risk of transmission through the air. Unconditioned spaces can cause thermal stress to people that may be directly life threatening and that may also lower resistance to infection. In general, disabling of heating, ventilating, and air-conditioning systems is not a recommended measure to reduce the transmission of the virus.

ASHRAE Core Recommendations for Reducing Airborne Infectious Aerosol Exposure are available HERE.

Mechanical Air Filters

- Filters consist of media with porous structures of fibers or stretched membrane material to remove particles from airstreams.

- The fraction of particles removed from air passing through a filter is termed “filter efficiency” and is provided by the Minimum Efficiency Reporting Value (MERV) from an ASHRAE 52.2 test is based on the filter efficiency.

- MERV ranges from 1 to 16; higher MERV = higher efficiency

- MERV ≥13 (or ISO ePM1) are efficient at capturing airborne viruses

- High efficiency particulate air (HEPA) filters are more efficient than MERV 16 filters.

- Filters must be sealed well to give the expected performance. Ensure the airflow passes through the filter and not around it due to leaks.

- The HVAC fans must be operating for the filters to clean the air. Run the HVAC system as much as practical.

- Some filters have charged media to increase particle removal with lower pressure drop. Since the efficiency of these filters often drops off with initial use, a MERV-A value, if available, will reflect the actual minimum efficiency better than a standard MERV value.

- Increased filter efficiency generally results in increased pressure drop through The filter. Ensure HVAC systems can handle filter upgrades without negative impacts to pressure differentials and/or air flow rates prior to changing filters.

- Upgrading and Improving Filtration

- Practical Approach to Increase MERV in an AHU

- Calculation Approach to Increase MERV in an AHU

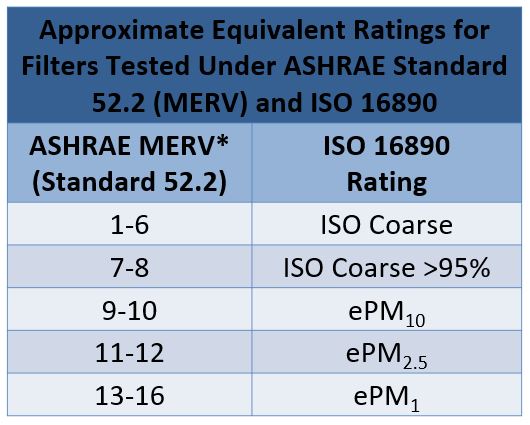

- Generally, particles with an aerodynamic diameter around 0.3 μm are most penetrating; efficiency increases above and below this particle size.

- Aim to achieve filtration efficiency similar to a MERV 13 filter. For filters in sequence, one or both can be upgraded to achieve the MERV 13 level or higher. For example, two MERV 11 filters (each 65% efficient) in sequence would be 88% efficient, which better than a MERV 13 filter (for 1-3 um particles).

- Outdoor air is free of viral particles. HVAC filters that only filter outdoor air do not need to be upgraded.

- Overall effectiveness of reducing particle concentrations depends on several factors:

- Filter efficiency

- Airflow rate through the filter

- Size of the particles

- Location of the filter in the HVAC system or room air cleaner

For more information, see the ASHRAE Position Document on Filtration and Air Cleaning.

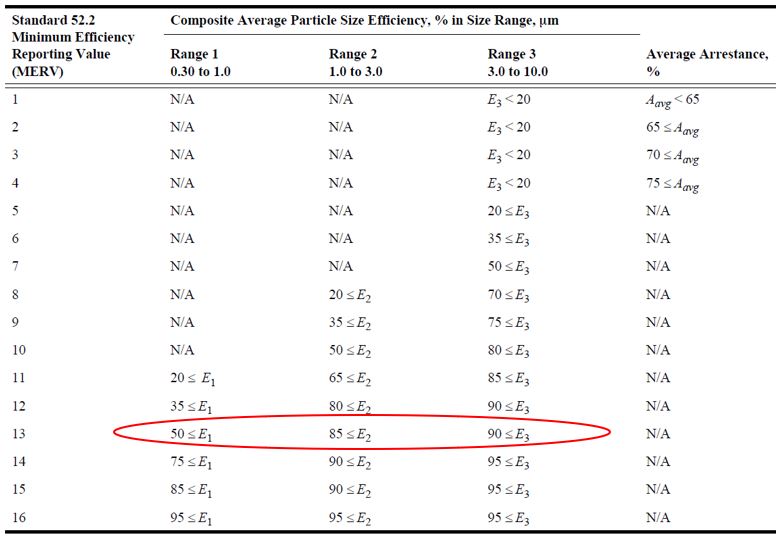

ASHRAE Standard 52.2-2017 Minimum Efficiency Reporting Value (MERV)

ASHRAE MERV vs. ISO 16890 Ratings

*MERV-A will give closer results. Charged media filters usually show a drop-off in efficiency with use. ISO 16890 captures this with an IPA condition step. ASHRAE 52.2 can capture this drop if the test is done with the optional Appendix J which gives the MERV-A. Thus, the MERV and the ePM ratings do not reflect the same testing. For charged media, the MERV will likely make the filter appear more efficient than the ePM rating.

High Efficiency Particulate Air (HEPA) Filters

- By definition, HEPA filters are at least 99.97% efficient at filtering 0.3 μm mass median diameter (MMD) particles in standard tests.

- Most penetrating particle size may be smaller than 0.3 μm, so filtration efficiency of most penetrating particles can be slightly lower.

Note: Numbers in graph represent MERV values.

Kowalski, W.J. and Bahnfleth, W.P., 2002. MERV filter models for aerobiological applications. Air Media, Summer, 1.

- HEPA filter efficiency is higher than MERV 16.

- It is usually not feasible to retrofit existing HVAC systems with HEPA filters due to high pressure drops and the likelihood that systems will need new filter racks to allow sufficient sealing to prevent filter bypass.

- Adding HEPA filters to systems that are not designed for them may cause significant damage.

- To function properly, HEPA filters must be sealed properly in filter racks.

- HEPA filters are often delicate and require careful handling to prevent damage and preserve performance.

- HEPA filters can be located in HVAC systems or in:

- In-Room or Portable HEPA Air Cleaners

- Pre-Assembled Systems (e.g., Sidestream bypass systems)

- On-site Retrofit Assemblies

Electronic Air Cleaners

- Include a wide variety of electrically-connected air-cleaning devices designed to remove particles from airstreams.

- Removal typically occurs by electrically charging particles using corona wires or by generating ions (e.g., pin ionizers) and:

- Collecting particles on oppositely charged plates (precipitators, ESP),or

- Charged particles’ enhanced removal by a mechanical air filter, or

- Charged particles’ deposition on surfaces including furniture and people

- The fraction of particles removed from air by an electronic filter is termed “removal efficiency.” Although the testing methodology of ASHRAE 52.2 can be used to determine the efficiency of many of these devices, they are not officially covered by that standard.

- It is critical to wipe the wires in electrostatic precipitators as silicone buildup reduces efficiency.

- Always follow manufacturer’s instructions when using electronic air filters.

-

Overall effectiveness of reducing particle concentrations depends on:

- Removal efficiency

- Airflow rate through the filter

- Size and number of particles

- Location of the filter in the HVAC system

- Maintenance and cleanliness of electronic filter components

-

For more information, see the ASHRAE Position Document on Filtration and Air Cleaning.

Gas-Phase Air Cleaners

- Gas-phase air cleaners are those used to remove ozone, volatile organic compounds and odors from the air.

- Most contain sorbent materials such as carbon (e.g., activated charcoal).

- While there may be exceptions, most sorbent beds alone are not generally efficient at removing viruses from airstreams.

- Carbon/sorbent impregnated fiber filters will remove particles; check for a MERV rating to show efficiency just as you do with standard particulate filters.

Ultraviolet Energy (UV-C)

- Ultraviolet energy inactivates viral, bacterial and fungal organisms so they are unable to replicate and potentially cause disease.

- The entire UV spectrum is capable of inactivating microorganisms, but UV-C energy (wavelengths of 100 – 280 nm) provides the most germicidal effect with 265 nm being the optimum wavelength for damaging DNA and RNA.

- The majority of modern UVGI lamps create UV-C energy with an electrical discharge through a low-pressure gas (including mercury vapor) enclosed in a soft glass or quartz tube, similar to fluorescent lamps.

- Roughly 95% of the energy produced by these lamps is emitted at a near-optimal wavelength of 253.7 nm.

- UV-C light-emitting diodes (LEDs) are emerging for use.

- Types of disinfection systems using UV-C energy:

- In-duct air disinfection

- Upper-room or upper-air disinfection

- In-duct surface disinfection

- Portable room decontamination

- Requires special PPE to prevent damage to eyes and/or skin from overexposure.

- The Illuminating Engineering Society (IES) Photobiology Committee published a FAQs on Germicidal Ultraviolet (GUV) specific to the COVID-19 pandemic.

For more information, see the ASHRAE Position Document on Filtration and Air Cleaning.

UV-C LEDs

- Have been common in the UV-A spectrum (315 – 400 nm)

- LEDs are starting to be produced in the 265-280 nm range

- Efficiency is dramatically less than current low-pressure mercury vapor lamps

- Minimal UV output compared to a low-pressure mercury vapor lamps

- For equal output, UV-C LEDs are more expensive than current low-pressure mercury vapor lamps

For more information, see the FAQs on Germicidal Ultraviolet (GUV) published by the Illuminating Engineering Society (IES) Photobiology Committee.

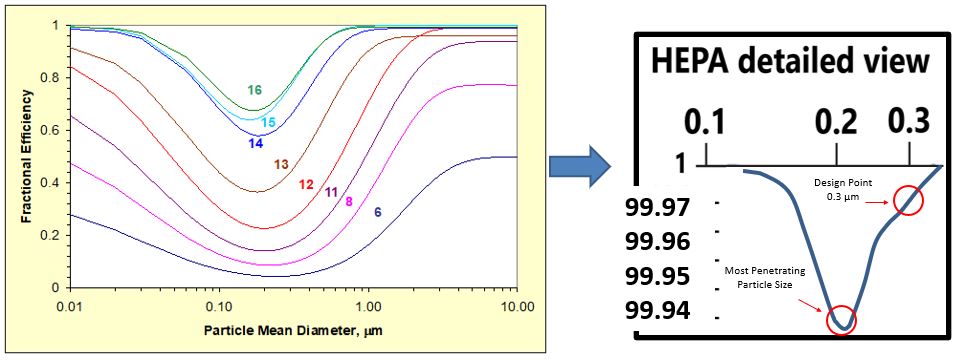

UV-C In-Duct Air Disinfection

- Banks of UV-lamps installed inside HVAC units or associated ductwork; positioned parallel or perpendicular to airflow

- Requires increased dose of UV to inactivate microorganisms on-the-fly as they pass through the disinfection zone. Due to limited exposure time, installations should observe these guidelines:

- Minimum target UV dose of 1,500 µW•s/cm2 (1,500 µJ/cm2)

- Designed for 500 fpm or slower moving airstream

- Minimum irradiance zone of two feet

- Minimum UV exposure time of 0.25 second

- Should be coupled with mechanical filtration

- Install the highest practical MERV filter that does not compromise system performance

- Layering of technologies increases overall air cleaning through capture and/or viral inactivation

Details on the UV Dose Recommendation for SARS-CoV-2

- A minimum UV-C (254 nm) dose of 611 µJ/cm2 should be applied for 90% inactivation of SARS-CoV-2. This extrapolates to a dose of 1222 µJ/cm2 for 99% inactivation of SARS-CoV-2 virus in air applications.

- It is advisable to build in appropriate safety margins to account for different environmental conditions such as air flow speeds, temperature and humidity levels, number of air changes, surface soiling, lamp ageing and system configuration, etc. A conservative minimum UV-C (254 nm) dose value of 1,500 µJ/cm2 is therefore suggested for 99% inactivation of SARS-CoV-2 in air.

UV-C Upper-Air Disinfection

- UV fixtures mounted in occupied spaces at heights of 7 feet and above. Requires a minimum of an 8-foot ceiling, but taller ceilings are preferred

- Non-reflective louvers or baffles collimate UV-C from fixture to create a safe disinfection zone above occupants' heads

- Consider when:

- Limited or no mechanical ventilation

- Congregate settings and other high-risk areas

- Economics/other

- Requires low UV-reflectivity of walls and ceilings

- Ventilation should maximize air mixing

- Use supplemental fans where ventilation is undersized or insufficient

- NIOSH upper-room design guidelines

UV-C In-Duct Surface Disinfection

- Banks of UV-Lamps installed inside HVAC systems, generally focused on:

- Cooling coils

- Drain pans

- Other wetted surfaces

- UV irradiance can be lower than in-duct air disinfection systems due to longer exposure times.

- Goals are:

- Even distribution of UV energy across the coil face

- Generally, 12 to 36 inches from the coil face

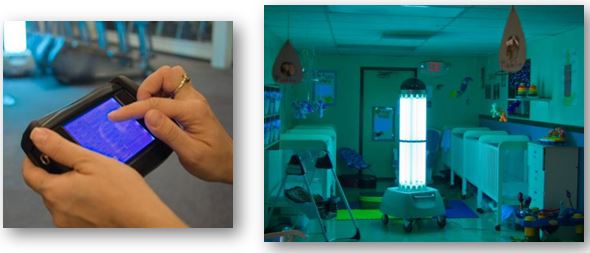

UV-C Portable Room Decontamination

- For surface decontamination

- Portable, fully automated units; may use UV-C lamps or Pulsed Xenon technology

- Settings for specific pathogens such as MRSA, C. difficile, both of which are harder to inactivate than coronaviruses

- >99.9% reduction of vegetative bacteria within 15 minutes

- 99.8% reduction of C.difficile spores within 50 minutes

(Rutala et al. 2010)

Special Precautions

- Exposure to UV-C energy can cause temporary eye and skin damage

- Photokeratitis (inflammation of the cornea)

- Keratoconjunctivitis (inflammation of the ocular lining of the eye)

- Symptoms may not be evident until several hours after exposure and may include an abrupt sensation of sand in the eyes, tearing and eye pain, possibly severe.

- Symptoms usually appear 6 to 12 hours after UV exposure

- Symptoms are fully reversible and resolve within 24 to 48 hours

- UV systems should be turned off before any system maintenance. Maintenance workers should receive special training before working on UV-C systems

- If exposures are likely to exceed safe levels, special personal protective equipment (PPE) is required for exposed eyes and skin.

- Eyewear that blocks UV-C energy

- Clothing, suits or gowns known to block UV exposure

Photocatalytic Oxidation (PCO) and Gaseous Hydrogen Peroxide

- Consists of a pure or doped metal oxide semiconductor material

- Most Common Photocatalyst is Ti02 (titanium dioxide)

- Activated by a UV light source

- UV-A (400-315nm)

- UV-C (280-200nm

- UV-V (under 200nm) Ozone can be formed at UV-V wavelengths

- Light mediated, redox reaction of gases and biological particles absorbed on the surface

- Some units claim disinfection from gaseous hydrogen peroxide

- Possible by-products formed by incomplete oxidation, including from gaseous contaminants

Photocatalytic Oxidation (PCO)

- Some air cleaners using PCO remove harmful contaminants to levels below limits for reducing health risks set by recognized cognizant authorities.

- Some are ineffective in reducing concentrations significantly; manufacturer data should be considered carefully.

For more information, see the ASHRAE Position Document on Filtration and Air Cleaning.

Bipolar Ionization/Corona Discharge/ Needlepoint Ionization and Other Ion or Reactive Oxygen Air Cleaners

- Air cleaners using reactive ions and/or reactive oxygen species (ROS) have become prevalent during the COVID-19 pandemic. New devices that are not mentioned elsewhere in this guidance likely fall into this category.

- High voltage electrodes create reactive ions in air that react with airborne contaminants, including viruses. The design of the systems can be modified to create mixtures of reactive oxygen species (ROS), ozone, hydroxyl radicals and superoxide anions.

- Systems are reported to range from ineffective to very effective in reducing airborne particles and acute health symptoms.

- Convincing scientifically-rigorous, peer-reviewed studies do not currently exist on these emerging technologies; manufacturer data should be carefully considered.

- Systems may emit ozone, some at high levels. Manufacturers are likely to have ozone generation test data.

For more information, see the ASHRAE Position Document on Filtration and Air Cleaning and CDC Response to ASHRAE ETF on Bipolar Ionization.

CDC Position on Emerging� Technologies for Air Cleaning

CDC does not provide recommendations for, or against, any manufacturer or product. There are numerous technologies being heavily marketed to provide air cleaning during the ongoing COVID-19 pandemic. Common among these are ionization, gaseous hydrogen peroxide, and chemical fogging disinfection. Some products on the market include combinations of these technologies. These products generate ions, reactive oxidative species (ROS, which are marketed using many names), or chemicals into the air as part of the air cleaning process. People in spaces treated by these products are also exposed to these ions, ROS, or chemicals.

While variations of these technologies have been around for decades, relative to other air cleaning or disinfection methods, they have a less-documented track record when it comes to cleaning/disinfecting large and fast volumes of moving air within heating, ventilation, and air conditioning (HVAC) systems or even inside individual rooms. This does not necessarily imply the technologies do not work as advertised. However, in the absence of an established body of peer-reviewed evidence showing proven efficacy and safety under as-used conditions, the technologies are still considered by many to be “emerging.”

As with all emerging technologies, consumers are encouraged to exercise caution and to do their homework. Registration alone, with national or local authorities, does not always imply product efficacy or safety. Consumers should research the technology, attempting to match any specific claims against the intended use of the product. Consumers should request testing data that quantitively demonstrates a clear protective benefit and occupant safety under conditions consistent with the intended use. When considering air cleaning technologies that potentially or intentionally expose building occupants, the safety data should be applicable to all occupants, including those with health conditions that could be aggravated by the air treatment. In transient spaces, where average exposures to the public may be temporary, it is important to also consider occupational exposures for workers that must spend prolonged periods in the space.

Preferably, the documented performance data under as-used conditions should be available from multiple sources, some of which should be independent, third-party sources. Unsubstantiated claims of performance or limited case studies with only one device in one room and no reference controls should be questioned. At a minimum, when considering the acquisition and use of products with technology that may generate ozone, verify that the equipment meets UL 867 standard certification (Standard for Electrostatic Air Cleaners) for production of acceptable levels of ozone, or preferably UL 2998 standard certification (Environmental Claim Validation Procedure (ECVP) for Zero Ozone Emissions from Air Cleaners) which is intended to validate that no ozone is produced.

Source: FAQ on “new air disinfection devices” at Ventilation in Buildings | CDC

Ozone

- Ozone (O3) is a reactive gas that can disinfect air and surfaces by killing/inactivating viruses, bacteria and fungi.

- Ozone is harmful for health and exposure to ozone creates risk for a variety of symptoms and diseases associated with the respiratory tract.

- ASHRAE’s Environmental Health Committee issued an emerging issue brief suggesting “safe ozone levels would be lower than 10 ppb” and that “the introduction of ozone to indoor spaces should be reduced to as low as reasonably achievable (ALARA) levels.”

- Should only be considered for disinfection on unoccupied spaces; it should never be used in occupied spaces.

- Available scientific evidence shows that, at concentrations that do not exceed public health standards, ozone is generally ineffective in controlling indoor air pollution.

- Section 5.7.1 of ANSI/ASHRE Standard 62.1-2019 states that air-cleaning devices shall be listed and labeled in accordance with UL Standard 2998.

For more, see EPA’s Ozone Generations that are Sold as Air Cleaners.

In-Room or Portable Air Cleaners

- Device is located in the room where air cleaning is desired. Place air cleaner where air intake and discharge are not impeded (e.g., not near furniture or behind curtains).

- Air is pulled into the device, and cleaned air is returned to the room. Flexible ductwork can be attached to some devices to allow strategic positioning of intake and/or discharge locations, including discharge outside the room to create pressure differences and/or create clean to less-clean directional airflow.

- Devices may include any or combinations of air cleaning technologies (filters, sorbents, UV, etc.). Users are advised to carefully determine that the application of the technology is appropriate for their need.

- Outlet air vents on in-room air cleaners should be placed carefully to avoid causing strong air currents blowing over one person onto others or blowing directly on surfaces that might enable reentrainment of virus particles.

- Many devices are rated by the Association of Home Appliance Manufacturers

- The rate of particle removal from air is termed the Clean Air Delivery Rate (CADR), typically in units of cubic feet per minute (CFM).

- CADR ≈ airflow rate × removal efficiency

- To reach a desired air exchange rate in air changes per hour (ACH):

ACH = CADR (cfm) × 60 (min/hr) ÷ room volume (ft3)

- See ASHRAE document: In-Room Air Cleaner Guidance for Reducing COVID19 In Air In Your Space/Room

Combining Air Cleaning Options

Chemical Disinfectants

- EPA reviews and registers antimicrobial pesticides, which include disinfectants for use on pathogens like SARS-CoV-2.

- Carefully read product labels and use as directed.

- Most products have a required contact or dwell time, which is the amount of time a surface must remain wet to kill a certain pathogen.

- Applying a product in a way that does not align with its intended use may render the product less effective.

- Products on EPA List N have not been tested specifically against SARS-CoV-2, however the EPA expects them to kill the virus because they:

- Demonstrate effectiveness against a harder-to-kill virus; or

- Demonstrate efficacy against another type of human coronavirus similar to SARS-CoV-2.

- All surface disinfectants on EPA List N can be used to kill viruses on surfaces such as counters and doorknobs.

- Guideline for Disinfection and Sterilization in Healthcare Facilities, 2008

Vaporized Hydrogen Peroxide (VHP)

- Systems are typically only used in healthcare settings and laboratories

- Liquid hydrogen peroxide (H2O2) is vaporized, and the vapor fills the space to disinfect all exposed surfaces.

- Space MUST be unoccupied during VHP treatment.

- Requires spaces to be sealed including all doorways, plumbing/electrical penetrations and HVAC supply and return vents to prevent vapor from escaping.

- After prescribed exposure times, remaining H2O2 vapor is scrubbed from space and converted back to oxygen and water before space can be safely reoccupied.

- The effectiveness and safety of VHP when generated inside active HVAC ducts and occupied spaces.

- VHP is hazardous at high concentrations, and lengthy exposure is often necessary to inactivate bacteria and viruses in sealed spaces.

Pulsed Xenon (Pulsed UV)

- High-powered UV lamps (generally containing xenon gas) used in rapid pulses of intense energy.

- Emits a broad band of visible and ultraviolet wavelengths, with a significant fraction in the UV-C band.

- Uses significantly higher power outputs than usual UV-C techniques

- Inactivates viruses, bacteria and fungi using the same mechanisms as standard UV-C systems

- Typically used for healthcare surface disinfection but can be used in HVAC systems for air and surface disinfection.

For more information, see the FAQs on Germicidal Ultraviolet (GUV) published by the Illuminating Engineering Society (IES) Photobiology Committee.

405 nm Visible Light

- Sometimes referred to a “Near UV,” although not in the UV spectrum

- Generally integrated into standard room lighting systems

- Kills bacteria and fungi via different mechanism than UV-C

- Targets and excites naturally-occurring porphyrin molecules inside organisms creating reactive oxygen species

- Effectiveness at killing viruses, including SARS-CoV-2, is not well documented

- Can provide continuous disinfection of air and exposed surfaces in occupied spaces

- In the FAQs on Germicidal Ultraviolet (GUV), the Illuminating Engineering Society (IES) Photobiology Committee notes that effectiveness is approximately 1000 times less than UV-C and the effective doses are not practical in an occupied environment

Far Ultraviolet

- Far UV spectrum is 205 to 230 nm

- Some inactivation of bacteria and viruses at the 207 nm and 222 nm range

- UV dose required to inactivate microorganisms may be higher at these wavelengths than in the typical UV-C range (250 – 280 nm)

- While safety concerns are reduced, far UV can still cause damage to eyes and skin

For more information, see the FAQs on Germicidal Ultraviolet (GUV) published by the Illuminating Engineering Society (IES) Photobiology Committee.

Summary

- COVID-19 is spread through the air

- Air cleaning can help mitigate disease transmission

- Options for air cleaning include:

- HVAC systems

- In-Room devices

- Technologies that can be effective include:

- Mechanical Air Filters

- Electronic Air Filters/Air Cleaners

- UV-C Systems

- Other Emerging Technologies

- Care and professional judgement should be taken to understand choices for filtration and air disinfection, pros and cons of each and impact(s) on existing buildings systems

HVAC System Maintenance and Filter Replacement during the COVID-19 Pandemic

- Consider letting the filter load up further than usual to reduce frequency of filter changes.

- Don’t let pressure drop increase enough to disrupt room pressure differentials

- Confirm filters are snug in their frames, preferably with gaskets to prevent filter bypass

- If desired, filters can be disinfected with a 10% bleach solution or another appropriate disinfectant, approved for use against SARS-CoV-2, before removal. Use appropriate PPE for the disinfectant.

- Filters (disinfected or not) should be bagged after removal from the duct and may be disposed of in regular trash.

- Remember that the virus will inactivate (die) over time and that it will not increase over time in the duct. It needs a host to replicate.

- For HVAC systems suspected to be contaminated with SARS-CoV-2, it is not necessary to suspend HVAC system maintenance, including filter changes, but additional safety precautions are warranted.

- The risks associated with handling filters contaminated with coronaviruses in ventilation systems under field-use conditions have not been evaluated.

- Workers performing maintenance and/or replacing filters on any ventilation system with the potential for viral contamination should wear appropriate personal protective equipment (PPE):

- A properly-fitted respirator (N95 or higher)

- Eye protection (safety glasses, goggles or face shield)

- Disposable gloves

- When maintenance tasks are completed, maintenance personnel should immediately wash their hands with soap and water and/or use an alcohol-based hand sanitizer.

Transmission Through Air in Toilet Rooms

- Studies with SARS CoV-1 have shown that toilet flushing can be a risk of generating airborne droplets and aerosols that could contribute to transmission of pathogens.

- Keep toilet room doors closed, even when not in use

- Put the toilet seat lid down, if there is one, before flushing

- Vent separately where possible (e.g., turn exhaust fan on if vented directly outdoors and run fan continuously)

- Keep bathroom windows closed as open windows could lead to re-entrainment of air into other parts of the building

Facilities/Maintenance – PPE Basics

- Refer to CDC Guidance on PPE use, especially banners at bottom of webpage

- N95 filtering facepiece respirators

- Protects the wearer from respiratory droplets AND aerosols.

- Can be an effective tool for worker protection with proper use.

- Require fit testing and a medical clearance to wear for work.

- Tested for efficiency against 0.3 micrometer airborne particles.

- Certified to filter at least 95% of these particles.

- Generally disposed of after each use, but pandemic has resulted in limited supplies. CDC issued Strategies to Optimize the Supply of PPE

- Silicone half mask respirators with N95 cartridges (or better) can be used instead of filtering facepiece respirators.

- Eye Protection

- Safety glasses (side shields preferred)

- Goggles

- Face shields

- Disposable Gloves

- Can be vinyl, rubber or nitrile

- Wearing two sets of gloves reduces the likelihood of cuts/punctures

- Can be worn under work gloves if necessary

- Disposable coveralls, gowns and/or shoe covers can be worn to enhance overall protection.

- After maintenance activities, wash hands with soap and water or use an alcohol-based hand sanitizer. Change clothes if soiled.

Disclaimer

This ASHRAE guidance document is based on the evidence and knowledge available to ASHRAE as of the date of this document. Knowledge regarding transmission of COVID-19 is rapidly evolving. This guidance should be read in conjunction with the relevant government guidance and available research. This material is not a substitute for the advice of a qualified professional. By adopting these recommendations for use, each adopter agrees to accept full responsibility for any personal injury, death, loss, damage or delay arising out of or in connection with their use by or on behalf of such adopter irrespective of the cause or reason therefore and agrees to defend, indemnify and hold harmless ASHRAE, the authors, and others involved in their publication from any and all liability arising out of or in connection with such use as aforesaid and irrespective of any negligence on the part of those indemnified.